Introduction

In today’s fast-paced industrial landscape, managing Maintenance, Repair, and Operations (MRO) efficiently is critical for any organization’s success. Traditional manual methods for MRO management can be time-consuming, error-prone, and hinder overall productivity. Enter the MRO ERP system – a comprehensive software solution designed to revolutionize and optimize MRO processes. In this article, we will delve into the various aspects of how an MRO ERP system improves efficiency, streamlines operations, and elevates businesses to new heights.

MRO ERP system improve efficiency

An MRO ERP system significantly enhances efficiency by offering the following key benefits:

Centralized Asset Management

An MRO ERP systems provides a centralized platform to manage all assets, including machinery, equipment, and facilities. It streamlines asset tracking, maintenance schedules, and work orders. This centralized approach ensures that all stakeholders have real-time access to critical asset information, reducing downtime and eliminating the risk of operational bottlenecks.

Streamlined Maintenance Planning

Efficient maintenance planning is vital to ensure the longevity and optimal performance of assets. The MRO ERP system utilizes data analytics and historical maintenance records to create preventive maintenance schedules. This proactive approach minimizes unplanned downtime, reduces maintenance costs, and prolongs the lifespan of assets.

Inventory Management Optimization

Maintaining the right level of spare parts inventory is essential for seamless operations. The MRO ERP system uses advanced algorithms to optimize inventory levels, ensuring that critical spare parts are always available when needed, without excess stock. This efficient inventory management eliminates wastage and surplus costs.

Seamless Procurement Processes

The ERP system streamlines procurement processes by automating purchase requisitions, vendor management, and purchase orders. By integrating with suppliers, businesses can maintain accurate inventory levels and ensure timely delivery of essential materials, ultimately reducing lead times.

Workforce Productivity Enhancement

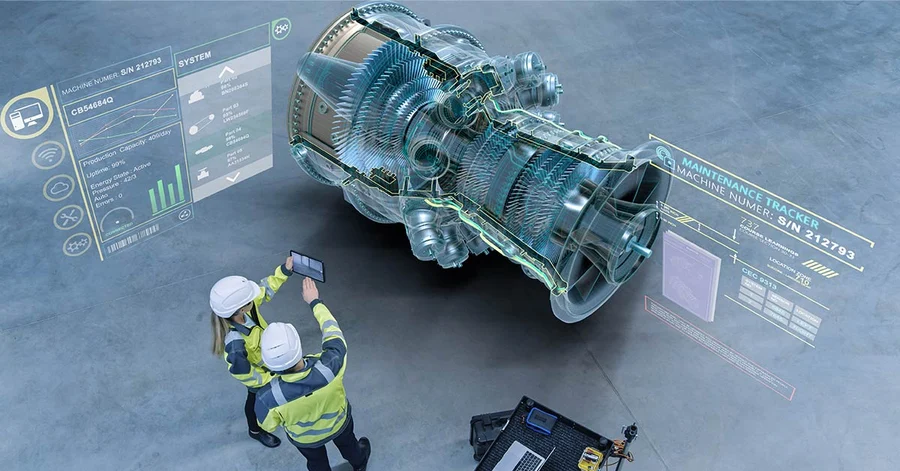

An MRO ERP system empowers the workforce with mobile access to data, allowing technicians to receive work orders, update progress, and report issues in real time. This mobile capability eliminates paperwork, enhances collaboration, and increases overall workforce productivity.

Enhanced Data Visibility and Analysis

Data-driven decision-making is at the core of any successful business. An MRO ERP system provides comprehensive data visibility, generating detailed reports and analytics on asset performance, maintenance costs, and overall efficiency. These insights help businesses identify areas for improvement and optimize their operations continually.

Integration with IoT and Predictive Maintenance

The integration of the MRO ERP system with the Internet of Things (IoT) enables predictive maintenance. Sensors and IoT devices monitor asset conditions in real-time, detecting anomalies and potential failures before they occur. This predictive maintenance approach prevents unplanned downtime and maximizes asset uptime.

Compliance and Safety Management

An MRO ERP system ensures compliance with industry regulations and safety standards. It tracks maintenance activities, certifications, and safety procedures, creating a safe and compliant work environment. This focus on safety mitigates risks and potential accidents, safeguarding both employees and assets.

Scalability and Flexibility

As businesses grow, so do their MRO needs. The MRO ERP system offers scalability and flexibility, adapting to changing requirements and accommodating additional assets and facilities seamlessly. This scalability features future-proofs businesses, ensuring the software remains effective in the long run.

Cost Reduction and ROI

Implementing an MRO ERP system may require an initial investment, but the long-term benefits outweigh the costs. By optimizing maintenance processes, reducing downtime, and enhancing productivity, businesses experience substantial cost savings and a higher return on investment (ROI).

How Does an MRO ERP system improve efficiency? The Real-Life Impact

To better understand the impact of an MRO ERP system on efficiency, let’s look at a real-life case study of XYZ Manufacturing Inc.

Case Study: XYZ Manufacturing Inc. Implements an MRO ERP System

XYZ Manufacturing Inc., a leading player in the heavy machinery industry, faced challenges with its manual MRO management system. Frequent breakdowns, unplanned downtime, and soaring maintenance costs were affecting their productivity and profitability.

In their quest for a solution, XYZ Manufacturing Inc. implemented an MRO ERP system, tailored to their specific needs. The results were remarkable:

- Reduced Downtime: With the implementation of predictive maintenance through IoT integration, XYZ Manufacturing Inc. Saw a significant reduction in unplanned downtime. The system detected potential failures early on, allowing for timely maintenance and minimized disruptions.

- Optimized Inventory: The MRO ERP system’s inventory management module helped XYZ Manufacturing Inc. Optimize its spare parts inventory. They were able to maintain the right level of stock, reducing excess inventory and avoiding production delays.

- Streamlined Work Orders: The ERP system’s mobile access enabled technicians to access work orders on their smartphones or tablets. This streamlined communication improved response times and enhanced overall workforce productivity.

- Cost Savings: By adopting preventive maintenance and optimizing inventory, XYZ Manufacturing Inc. experienced substantial cost savings. The ROI of implementing the MRO ERP system exceeded expectations.

The success of XYZ Manufacturing Inc. serves as a testament to the efficiency-boosting capabilities of an MRO ERP system. This case study underscores the importance of embracing digital transformation for modern-day businesses.

Conclusion

In conclusion, an MRO ERP system is a game-changer for organizations looking to enhance their efficiency, productivity, and overall operations. By centralizing asset management, streamlining maintenance planning, optimizing inventory, and integrating with IoT, this comprehensive software solution revolutionizes the way MRO processes are managed.

So, how does an MRO ERP system improve efficiency? The answer lies in its ability to revolutionize maintenance, repair, and operations management, bringing businesses closer to achieving their goals and objectives.

FAQs

What is an MRO ERP system?

An MRO ERP system is a comprehensive software solution designed to manage and optimize Maintenance, Repair, and Operations processes. It streamlines asset management, maintenance planning, inventory control, procurement, and data analysis, leading to improved efficiency and reduced operational costs.

How does an MRO ERP system integrate with IoT?

The integration of an MRO ERP system with the Internet of Things (IoT) involves connecting sensors and devices to assets. These IoT devices monitor asset conditions and performance in real-time, enabling predictive maintenance and minimizing downtime.

Is an MRO ERP system suitable for small businesses?

Yes, an MRO ERP system is scalable and can be tailored to suit the needs of small businesses. Implementing an MRO ERP system at an early stage allows small businesses to optimize their operations and prepare for future growth.

Can an MRO ERP system improve workplace safety?

Absolutely. An MRO ERP system ensures compliance with safety regulations and tracks maintenance activities, contributing to a safer work environment. By mitigating risks and preventing accidents, the system enhances workplace safety.

How long does it take to implement an MRO ERP system?

The implementation duration of an MRO ERP system depends on the size of the organization, the complexity of requirements, and data migration. Typically, it can take several months, but the benefits start to show almost immediately after deployment.

Is employee training necessary for using an MRO ERP system?

Yes, employee training is essential for the successful adoption of an MRO ERP system. Proper training ensures that employees can effectively utilize all the features of the MRO ERP system, maximizing its benefits. Training sessions are designed to familiarize users with the interface, data entry, reporting, and maintenance workflows.

More Stories

What Are The Benefits Of Self Storage For Homes And Offices

Unlocking the Potential: MRO ERP Software for Aviation

Finding the Best SEO Experts in San Jose, CA