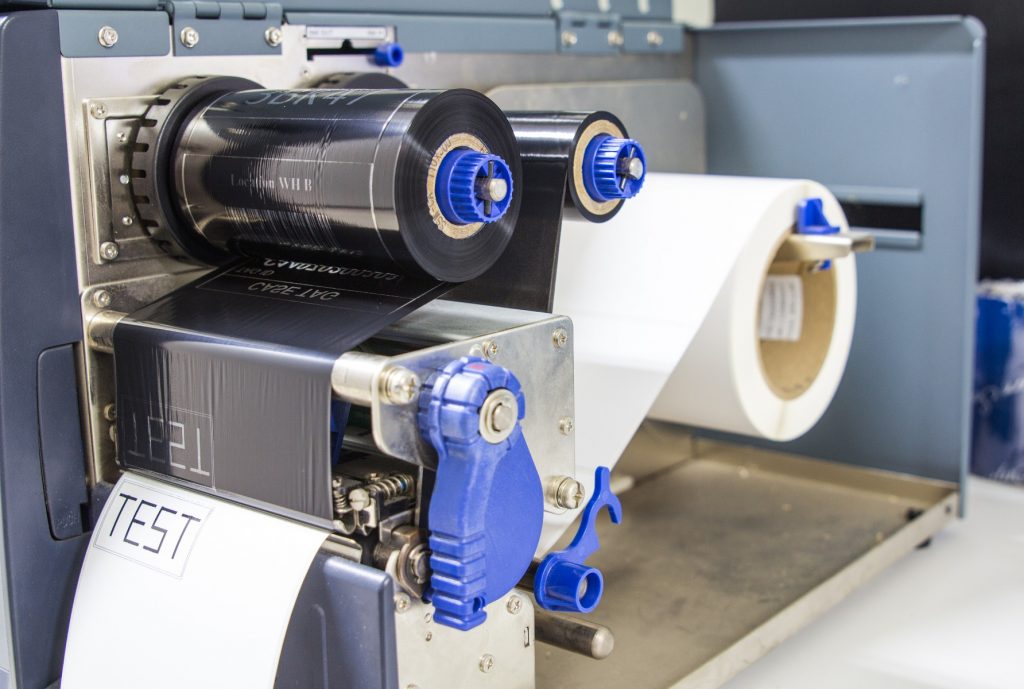

Ink for the thermal transfer method is usually made of wax, resin, or a wax/resin hybrid, depending on the project’s needs. The improper thermal transfer ribbon not just degrades the quality of your printed labels but can also cost you money if you don’t match the ribbons to your product material correctly.

Here’s a quick guide to help you understand the differences between thermal transfer ribbons and which ones are best for your label requirements.

Thermal Transfer Printers Benefits & Drawbacks

Advantages

Thermal printers offer several benefits to enterprises that need to print large labels, exceptionally long-lasting ones such as barcodes.

- Thermal labels are more durable than regular ink labels and can withstand a variety of circumstances. This ensures they won’t fade in direct sunlight, smear, or distort when exposed to oils or extreme temperatures.

- Unlike inkjet or laser printers, thermal label printers can generate massive labels in milliseconds rather than in seconds.

- Thermal transfer printing creates rich, high-resolution graphics in color or black-and-white on a wide range of substrates. Barcodes, text, and graphics have excellent resolution.

- Thermal transfer printing employs ribbon as the transfer agent, resulting in chemically resistant graphics and long-lasting.

- Thermal transfer printers have a high print speed and require little upkeep.

- Additional customization to labels can be added using transfer printing without worrying about fading difficulties over time.

Disadvantages

Producers can use thermal stickers on exposed surfaces that may get wet or dirty without concern of the label wearing out or pulling off since they are considerably more resilient than traditional labels. Thermal transfer printers also have fewer common printer difficulties, such as jams.

- Each ribbon is only used once. On the other hand, thermal transfer ribbons are very easy to dispose of and are less harmful to the environment than the other printing processes listed.

- Labels and ribbons are both required. It can be challenging to load ribbons.

- The ribbon must be the same color as the face stock.

- A single-pass ribbon can be inefficient if printed on long levels.

The thermal transfer printing technique is incredibly adaptable, allowing users to print sharp, durable pictures on a virtually infinite number of substrates, which is a primary requirement of most barcoding projects. Thermal transfer printing is the most excellent method for barcode printing in the business, and there is no other option better when it comes to pure quality and dependability.

More Stories

What Are The Benefits Of Self Storage For Homes And Offices

Unlocking the Potential: MRO ERP Software for Aviation

Finding the Best SEO Experts in San Jose, CA